Clients' Working Site

Advantage

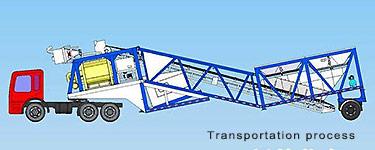

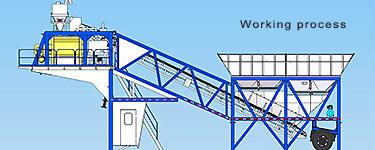

1. Adopting module structure, designed as per the loading of container standard. All modules are in one trailing unit. Easy for installation and disassembly. Fast for moving.

2. Main mixing unit is JS1000 double-shaft, forced concrete mixing mixer, with good mixing quality, high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic and concrete with any mixing ratio.

3. All scaling elements and control elements of scaling unit are imported elements and controlled by computer, guaranteeing completely accurate scale and stable function.

4. Platform or ladder is equipped to each part needing maintenance and repairing. Good for maintenance.

5. The whole system adopts complete automatic system via computer, with dynamic panel display, to show clearly of the running of each part. Visualized monitor interface provides clear and accurate observing to the site working procedure. Table or list can be print out.

6. Electrical control system adopts import elements, providing a stable and powerful function. Automatic test for the abnormal working condition, Word, sound, light alarm, easy and good for the maintenance and trouble shooting.

Specification

|

1. MIXING SYSTEM Twin Shaft Concrete Mixer: JS1000 Volume: 1600 L Capacity: 1000 L Paddle quantity: 2*8 pieces Paddle Speed: 25.5 r/min Mixing Motor: 2*18.5kw |

2. CONTROL SYSTEM: PLC command and control operation Main electrical components: Schneider 17colorful computer Manuel and Auto Control is freely changeable |

|

3. AGGREGATE SYSTEM 3.1.1Aggregate Batcher PLD1600 Volume: 4×8m3=32 Sort of aggregate: 4 Capacity: 80 m3/h Power: 11 kw Sand vibrator: 0.37kw×2 3.2. Aggregate Belt Conveyor 1 unit Width:800 mm Length: 18456mm Speed: 1.6 m/s Motor: 7.5 kw |

4. WEIGHING SYSTEM: 4.1 Aggregate weighing 1 unit Weighing Capacity: 1.6 m3Precision: ±2% 4.2 Cement weighing 1 unit Weighing Capacity: 1m3 Precision: ±1% 4.3 Water Weighing 1 unit Weighing Capacity: 150 kg Precision: ±1% 4.4 Additive Weighing 1 unit Weighing Capacity: 40 kg Precision: ±1% |

|

5. CEMENT SYSTEM Cement Silo: 30 Ton Cement Screw Feeder: 2 units Diameter: Φ219mm Length: 11.8 m |

6. ADDITIVE SYSTEM Additive silo capacity: 1 m3 Pneumatic valve: Φ50 mm Pump: 3kw |

|

7. WATER SYSTEM Submersible pump: 3kw Water pump: 0.75kw Water tank: 3 m3 |

8. AIR SYSTEM Air Compressor: 1 unit Power: 7.5kw Pressure: 0.7Mpa Airflow: 0.8 m3/min |

Tags: self loading cement mixer mini concrete batching plant portable batch plant wheel mobile jaw crusher d3522 mobile concrete mixer pump price in bangladesh in Libreville hydraulic cone crusher loader backhoe types of concrete pumps in Abuja Ultrafine Powder Production 5 yard concrete mixer truck concrete mixer 1 bagger for sale philippines

Products

Concrete Mixers

- SICOMA Double Shaft Concrete Mixer

- Self-loading Mobile Concrete Mixer

- Concrete Mixer with Pump

- JZR Diesel Driven Concrete Mixer

- JS series Concrete Mixer

- MP Planetary Concrete Mixer

- European Tech.Twin shaft Concrete Mixer

- JZ series Concrete Mixer

- SICOMA Planetary Concrete Mixer

- DJBT40 Diesel Concrete Mixer Pump

Concrete Batching Plant

Concrete Conveying Plant

- HBT/DHBT series Concrete Pump

- Truck-mounted Concrete Boom Pump

- Truck Mounted Concrete Pump

- Elevator shaft Self-climbing Concrete Placing Boom

- Mobile Hydraulic Concrete Placing Boom

- Floor climbing Hydraulic Concrete Placing Boom

- Concrete Transit Mixer on Truck

- XBS/DXBS Fine Stone Concrete Pump

- Concrete Mixer Truck

- 6cbm Concrete Truck Mixer

Related Concrete Equipment

Concrete Block Making Plant

NEWS

- Invitation to Visit Us at EXCON 2024 - Peru's Premier Construction Exhibition

- HAMAC Team Celebrates International Women's Day with a Cozy Gathering

- Vision for 2025 - Pioneering Innovation, Excellence, and Shared Success

- HAMAC Machinery Christmas Eve Celebration

- Celebrating Winter Solstice at HAMAC Machinery

- Boost Your Business This Christmas: Exclusive Deals on HAMAC Equipment

- Hamac Construction machinery Help Saudi Arabia's City of the Future in NEOM

- Hollow Brick Making Machine Price In China

- pros and cons asphalt vs concrete driveway

Get Quote

Get Quote Chat Online

Chat Online