Concrete Block Making Plant

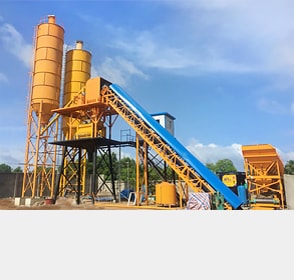

The using of Traditional sintered clay brick destroys a lot of field soil, wastes the land resources and pollutes the environment. With the augmentation of the concept of environmental protection, the unburned concrete block making machine arises at the historic moment. With the use of coal ash, cinder, coal gangue, or other industrial wastes and river sand, gravel, cement, etc. to produce different type of hollowing block, perforated brick, curb, paver, grass-planting brick, slope protection brick etc.

1. Batching plant: Controlled by PLC system, it can dose automatically according to the formula and then convey them into mixer.

2. Mixer: it can mix any materials for concrete making. The ready mixed concrete will be delivered to block shaping machine by belt conveyor.

3. Block shaping machine: It is controlled by PLC system, hydraulic power transmitted, forming under vibrating and pressurization. It can produce different types of blocks curb or paver block by using different moulds.

4. Stacker. Controlled by PLC system, it will pile the blocks up to 10 layers very steadily.

QT4-15 concrete block making machine works in Ica, Peru

Application Country: Ica, Peru

QT4-15 concrete block making machine works in Ica, Peru

Application Country: Ica, Peru

Jaw Crusher

Jaw Crusher

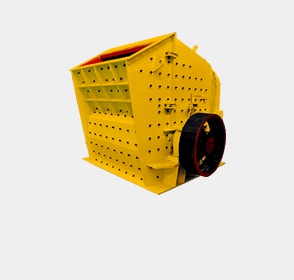

Impact Crusher

Impact Crusher

S series Spring Cone Crusher

S series Spring Cone Crusher

Stationary Concrete Batching Plant

Stationary Concrete Batching Plant