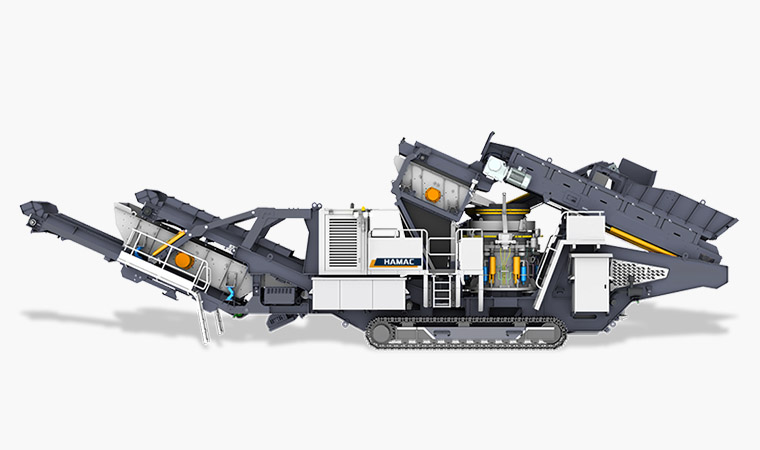

Usage of tracked crusher

Tracked crusher and screens are used widely in the world for different projects as below:

- 1. Widely used in mines, coal mines, recycling of garbage and construction waste, earthwork engineering, urban infrastructure, roads or construction sites.

- 2. Processing of topsoil and other materials; separation of viscous aggregate; construction and blasting industries; screening after crushing; quarrying industry.

Features and advantages

- 1.Fuel saving, environmental protection and low cost;

- 2.Light weight, compact design and convenient transportation;

- 3.Attached power package adopts optimized design.

- 4.Pre-screening system can increase crushing efficiency greatly.

- 5.It adopts heavy-load crawler chassis, hydraulic drive and self-powered. According to different project needs, it can be equipped with jaw crusher, impact crusher, cone crusher, vertical shaft impact crusher, vibrating screen and supporting equipment to operate alone or in multiple stages to form a combined crushing and screening operation system.