What is compound cone crusher?

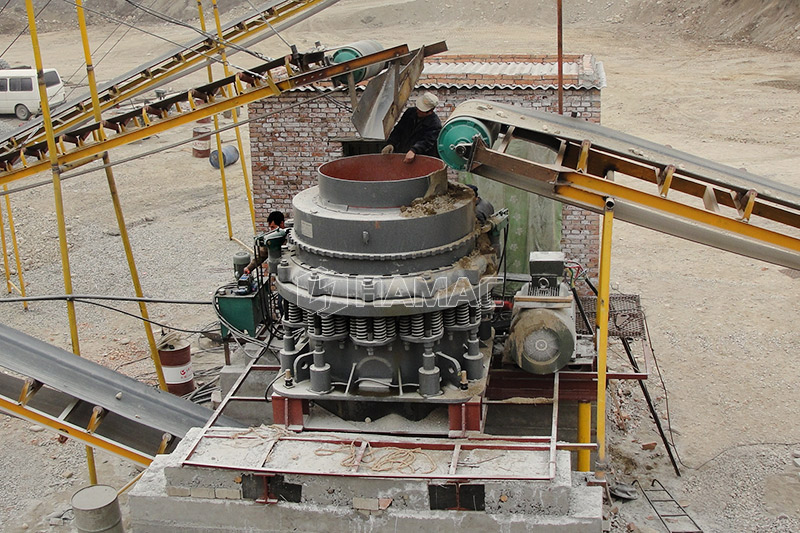

Compound cone crusher is one of different types of cone crusher for sale. It is more advanced than spring cone crusher, but also include the advantages of hydraulic cone crusher. That is why it is called as compound cone crusher.

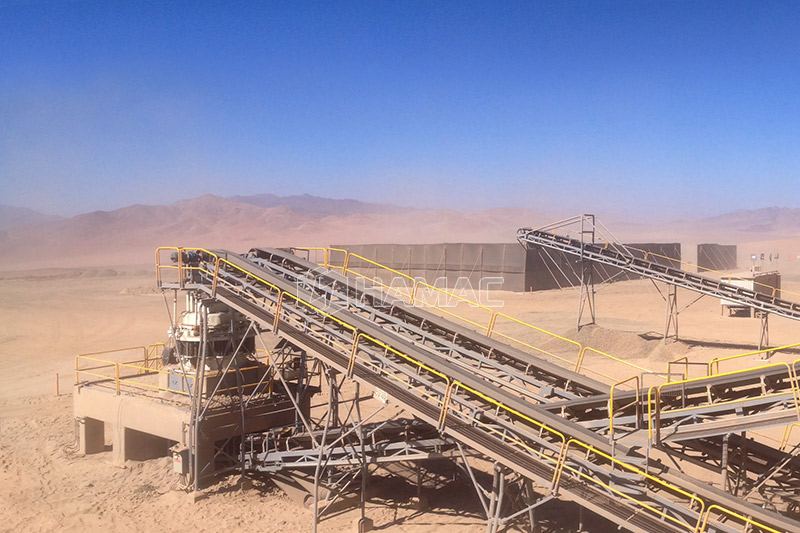

This series compound cone crusher are divided into coarse crushing, medium coarse crushing, fine crushing according to the requirements of crushing operation.HMC Series compound cone crusher has hydraulic clearing system, hydraulic opening adjusting function, easy for replacing concave and mantle, decreasing management and maintenance cost, It is widely used for medium and fine crushing of granite, basalt, disbase, cobble, cobblestone, iron ore etc.

Working Principle of compound cone crusher

When the cone crusher plant is working, the moving cone of the cone crusher machine makes a swinging motion around the fixed cone. Therefore, the cone crusher bowl liner of the movable cone and the fixed cone of the crusher are sometimes approached and sometimes separated, so that the stone or mineral ore are continuously impacted, squeezed and bent in the crushing cavity to realize the crushing of the materials, and complete the crushing and discharging. The surface of the crushing cavity is covered with a wear-resistant high manganese steel lining plate. The size of the discharge opening is adjusted hydraulically.

Advantages of compound cone crusher for sale

Compared with the S series Symons cone crusher and traditional PY spring cone crusher, there are many advantages of the compound cone crusher for sale as below.

- 1. It only takes 2 hours to replace the cone crusher concave and mantle, reduce the downtime;

- 2. Crushing ratio is bigger, feed opening is bigger, discharge opening is smaller, greater eccentricity of main shaft. Therefore, the output capacity per unit time is larger.

- 3. The main shaft speed is increased on the basis of the traditional spring cone crusher machine, which makes the utilization rate of electric energy high and reduces the cost.

- 4. Multiple crushing cavity types: HMC series compound cone crusher has a special cavity design, and users can choose a proper cavity type with higher crushing efficiency, uniform product particle size, good stone shape, uniform wear of cone crusher concave and cone crusher mantle and long service life according to application requirements.

- 5. Dry oil seal and dustproof; HMC series compound cone crusher has unique dustproof sealing structure and reliable sealing effect. Its performance is far better than traditional water sealing, which prolongs the replacement cycle of lubricating oil and the use of bearings, bearing bushes, gears and other parts long life, suitable for use in areas with little or no water.

- 6. Daily operation and maintenance costs are low. The material selection and structural design of the cone crusher parts are reasonable, and the service life is long; the crushing force arm is long, which reduces the sliding bearing, the crushing efficiency is high, the particle size of the crushed products is uniform, and the cyclic load is reduced; the hydraulic adjustment, locking and cavity cleaning system is easy to be operated, which improves the cone crusher machine operation rate; low power consumption and reasonable distribution.

How to extend the life of cone crusher?

Cone crusher machine is an important role in the stone crusher plant, it is almost the most expensive machine. If its life can be extended, the end user will save a lot in the next years. Here are some tips to extend the life of cone crusher for sale.

1. Stop feeding before the cone rock crusher stops:The feeding should be stopped first, and the material in the cone crusher machine should be discharged completely, and then the main motor and lubricating motor should be turned off in sequence. If the cone crusher machine is stopped with stone in it, it is easy to cause damage to the cone crusher parts;

2. Maintenance of the cone crusher:When the compound cone crusher is shut down, it is necessary to check whether the fastening bolts are firm and the degree of wear of the easily worn parts, and whether they need to be replaced.

3. Start of the compound cone crusher:The oil pump and cooling system should be started, and the crusher motor should be started after the oil circuit is unblocked. Because the cone crusher is a heavy-duty equipment, no matter what type it is, it should be started with no load.

4. Operation of the compound cone crusher:For the cone crusher that has been started, it should be idling for a few minutes first. When idling, check the base, guard plate chain etc. If there is no abnormality, start feeding. If the cone rock crusher is newly installed, the idle time should be longer, and the material can be fed after two to three work shifts. The feeding of the cone crusher must be continuous and uniform to prevent overload, and the feeding amount should be consistent throughout the width of the feeding opening, so that the cone crusher concave and cone crusher mantle can be uniformly worn and the life of the easily worn parts can be prolonged relatively.