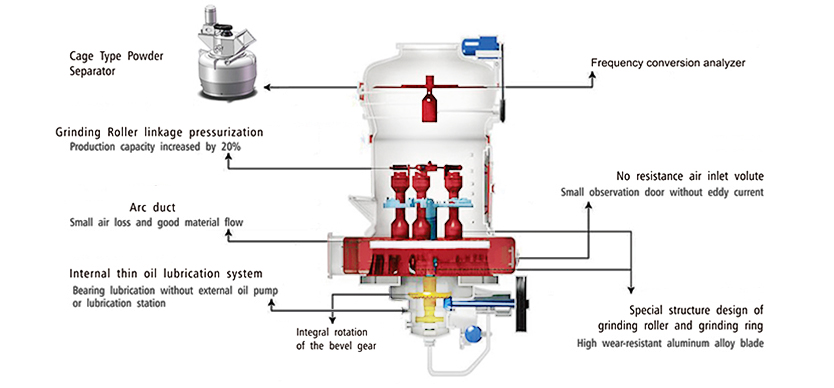

Advantage of MTW series grinding mill

Volute design, lower energy consumption

MTW European Tech. grinding mill adopts resistance-free air inlet volute design, which makes the tangential airflow smoother, the material fluidity better, and the energy consumption lower.

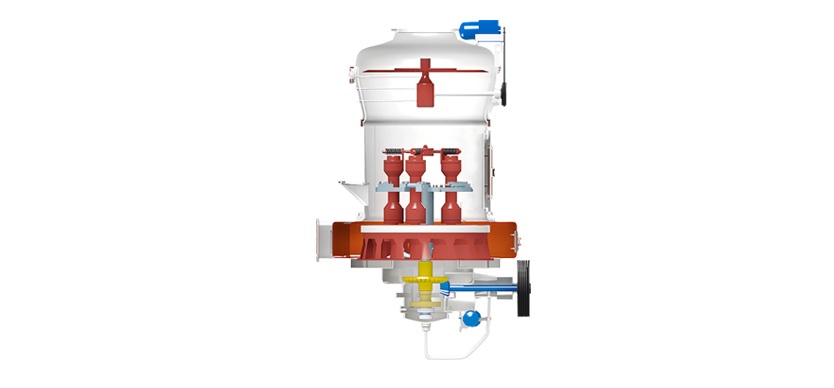

Working Principle of grinding mill

After crushing, qualified materials are evenly and continuously fed into the main machine grinding chamber for grinding by the variable frequency belt feeder. The ground materials are sent to the powder selector by the fan airflow for classification.

Under the action of the analyzer, materials that do not meet the fineness requirements fall into the grinding chamber for re-grinding, and qualified materials follow the airflow through the pipeline into the cyclone powder collector for separation and collection, and are discharged as finished powder through the discharge device. The separated airflow enters the fan through the return air duct at the upper end of the cyclone powder collector.

The system operates under positive and negative pressure conditions, and the equipment is equipped with a pulse dust collector, which is environmentally friendly.