What is mobile crusher for sale?

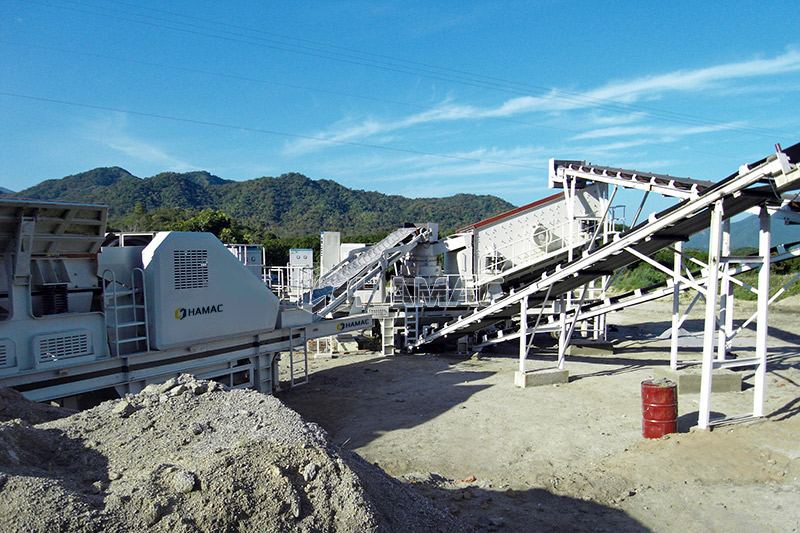

Mobile crusher for sale is a crushing plant which is truck-mounted or crawler mounted. It can be quickly assembled and moved in different working sites.

This series mobile crushing and screening plant is the crushing equipmentfor rocks and construction waste, which is explored and developed by our company. It expands the conception of primary and secondary crushing operation. To meet our customer’s requirements is the aim of this design. Removing customers’ operation obstacles caused by space and environment is our first and foremost solution. With the new concept of “PROCESS THE RAW MATERIAL NEAR TO SOURCE AND DESTINATION”. We really and truly supply simple, high efficiency and low cost mobile crusher for sale.

Different types of mobile crusher we have

According to the different usage of the mobile crusher for sale, HAMAC can provide our clients with mobile jaw crusher, mobile impact crusher, mobile cone crusher, mobile screening plant and the complete mobile crusher and screen production line. The mobile crusher plant is a customized product, its designed is based on the requirement of clients for different projects.

For different working sites, HAMAC can provide our clients with tire type mobile crusher plant and crawler type mobile crusher plant as options.

Features of mobile crushing and screening plant for sale

- 1. The mobility is flexible The tire-type mobile crushing plant for sale has a high chassis and a small turning radius, which is convenient for driving on ordinary roads and more convenient for driving in the rough and harsh road environment in the crushing field. It saves time for a quick entry into the construction site.

- 2. Reduce material transportation costs In line with the principle of "processing material at site", the materials can be crushed on-site, eliminating the intermediate links of re-crushing and processing materials when they are transported away from the site, and greatly reducing the transportation costs of materials.

- 3. The operation function is direct and effective The integrated tire series mobile crushing station can be used independently, and can also provide more flexible process configuration according to the customer's requirements for the material type and product in the process, to meet the user's mobile crushing, mobile screening requirements etc, the cost can be minimized.

- 4. Stable performance and easy maintenance Mobile wheeled crushing plants include jaw crusher series, impact crusher series, cone crusher series and VSI crusher series etc. All these types of crushers are of high efficiency, multi-function and good quality. They are reasonable in design and light in weight, brilliant crushing ability. With the very reliable and safe quality guarantee, it can meet the demands of coarse, medium and fine crushing, and screening as much as possible.

How to choose the suitable model of mobile crushing and screening plant?

Normally speaking, a mobile crushing and screening plant include a mobile primary jaw crusher, a mobile secondary crusher with vibrating screen on it, and then connect the working flow by the belt conveyors. When you want to invest on a mobile crushing and screening plant, the below tips need to be considered.

- 1. The stone size before crushing, it depends on the model of mobile jaw crushing plant. Because we want to consider the shipping and installation of the mobile jaw crusher. The total weight of this machine should be strictly controlled. So, for the mobile jaw crusher, its model can not be too big. Normally speaking, the jaw crusher for mobile type are PE500*750, PE600*900 and PE750*1060;

- 2. The output size of final aggregates and sand. With this information, we will choose the right model of secondary crusher and vibrating screen. For example, if the output size you need is 4 kinds, we will choose a vibrating screen with 4 decks screen mesh. If the aggregates you need is smaller, we will choose short head cone crusher;

- 3. Capacity. How many tons per hour or cubic meters per hour you want to process?

We have to consider these three factors together, the capacity will be the first factor to be considered. If the stone size is big, but the capacity is lower. Then you have to process the raw material stone in advance so that it can be fed into the primary crusher for crushing.

Mobile rock crusher VS stationary rock crusher

Mobile and stationary crusher are two different types crusher machine for sale. We conclude the difference between these two types stone crusher so that you can have a clear idea on them.

| Items | Stationary rock crushing plant | Mobile rock crushing plant |

| Project duration | Long time, it will be installed in a quarry or mine, for long time work. | Suitable for short time projects, needs to be moved between different working sites frequently; |

| Time for installation and commissioning | longer time, because you need time for foundation, assembly. | Shorter time, no need to prepare foundation, and the crusher machine was tested well in the factory already |

| Capacity | 30-600m3/h, for stationary type, the capacity can be higher because it is installed on the foundation; | 30-150m3/h, because you want to move it by a tractor truck, so it can not be too big and heavy; |

| Full portability | It is fixed on the concrete foundation or steel structure foundation. It will take time and cost to move it between different working sites; | It is mounted onto a truck chassis, allowing for easy transportation. But you still need to disassemble some parts so that it can be moved on the road. |

| Price | If the capacity is the same, the stationary one will be cheaper. | If the capacity is the same, the mobile type will be more expensive. |

| Shipping | Can be put into the container, sea freight is lower | Delivered by RORO, flat rack or bulk vessel, it may take longer time to be shipped; |