What is the S Series Symons Cone Crusher ?

S series Symons Cone Crusher is an advanced cone rock crusher which represents the domestic advanced technology level. For years, HAMAC has been using the US-developed advanced crusher technology. This series cone crusher machine is widely used in metallurgical, construction, chemical and building material industry, suitable for hard and medium hard materials such as mine ore, limestone, quartz, granite, sandstone and so on. It is proven that the crusher with worldwide performance and reliable quality has gained the customers' praise. It is an ideal cone crusher almost the same as original Symons cone crusher for sale.

How does a cone crusher work ?

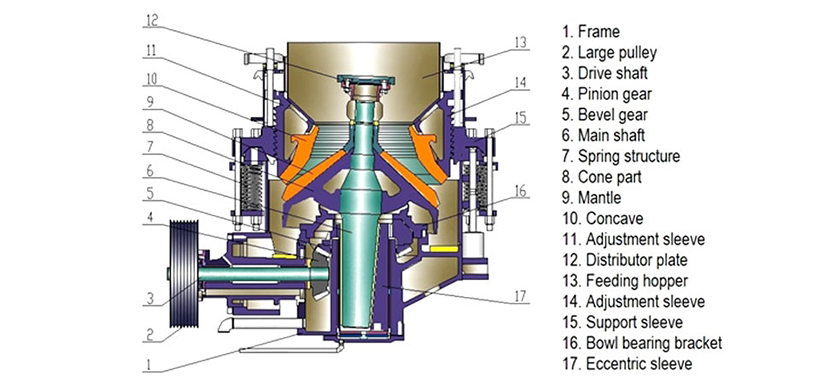

Motor drives eccentric bushing to rotate via V-belts, pulley, shaft, pinion, and gear. The eccentric bushing causes the mantle to rotate in an oscillating motion, moving it closer and farther from the cone crusher concave. As a result, the stone is gradually crushed into smaller sizes by the compression and shear forces. The continuous motion of the mantle ensures efficient material size reduction, while the hydraulic system allows for easy adjustment of the crusher settings. This is the working principle of a cone crusher.

Symons cone crushers for sale

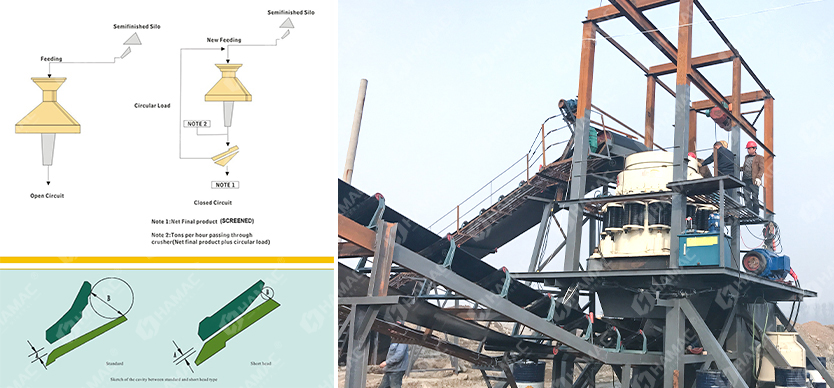

For this S series Symons cone crusher, there are different types and models for sale. They are designed for different application. According to the crushing cavity, there are two types cone crusher for sale. Standard cone crusher and short head cone crusher. Standard cone crusher is usually used as a secondary crusher, short head cone crusher is usually used a tertiary cone crusher to get smaller sizes aggregates and sand. According to the cone crusher sizes, HAMAC can provide Symons 3ft cone crusher, 4.25ft cone crusher, 5.5ft cone crusher and 7ft cone crusher. Welcome your inquiry.

Typical flow chart of cone crusher plant

When a cone crusher machine is working together with the jaw crusher machine and vibrating screen for sale in a whole stone crusher plant, there are two different typical flow charts of cone crusher plants. In the first flow chart, material is initially fed into the jaw crusher for primary crushing. Afterward, the material is sent to the vibrating screen to separate different sizes, with the suitable sizes passing to the cone crusher for secondary crushing. In the second flow chart, the material is pre-screened before entering the cone crusher, allowing for more efficient processing and reducing unnecessary wear on the crusher. Both flow charts aim to ensure continuous production with optimal efficiency.