What is Planetary Concrete Mixer?

PlanetaryPlanetary concrete mixer for sale is an ideal concrete mixer for high quality concrete and other materials. Some clients call it as pan concrete mixer. It is commonly found in Precast and Product concrete plants.

What we provide is a new convection planetary concrete mixer, rather than a simple vertical shaft planetary concrete mixer, which can achieve high homogeneity of the material being mixed in the shortest time.

Because it is vertical shaft mixer, and there is planetary rotary device to mix the concrete exclude the main rotary mixing device. That is why it is called planetary concrete mixer. You can see how the planetary concrete mixer mix the material via the below picture.

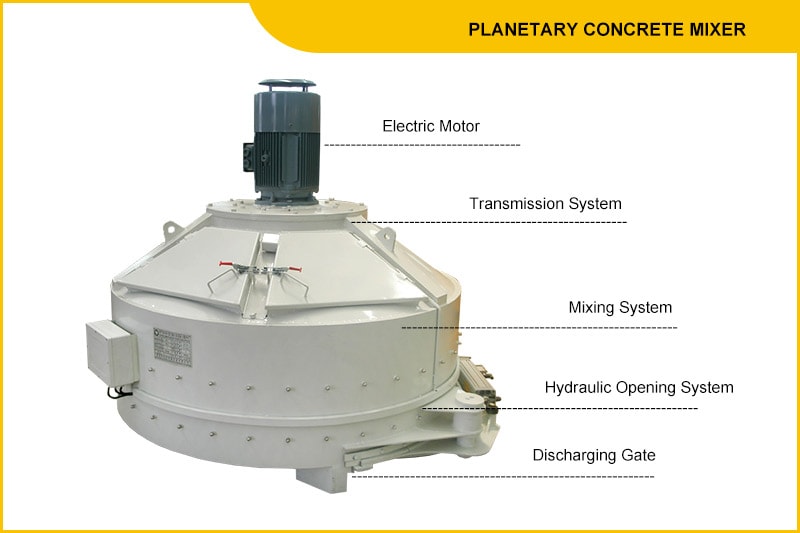

Components of a planetary concrete mixer

For a planetary concrete mixer, it consists of electric motor, gearbox, transmission system, mixing system, hydraulic opening system, discharging gate etc.

For different models of planetary concrete mixer, they have different quantities of planetary. For the mixing blades, there are several options, for example, it can be equipped with knife type blade to cut the additive such as steel fiber into the concrete.The discharging gate can be designed one, two or three.

A manual opening device is equipped in case the hydraulic opening does not work.

Advantages of Planetary Concrete Mixer for sale

1. The vertical shaft planetary concrete mixer adopts the self-researched planetary mixer gearbox reducer with high strength, good impact resistance, reasonable speed configuration, large output torque, low noise during operation, high reliability and easy maintenance.

2. The planetary vertical shaft mortar mixer adopts a uniquely developed planetary mixing mode. The rotation and revolution are combined. The single motor drive eliminates the phenomenon of material output being out of synchronization. The connection between the motor and the planetary mixer reducer adopts a hydraulic coupling, it makes the rotation speed adjustable, electric energy saved and transfer of energy rapidly.

3. According to the characteristics of concrete mixing materials, the lining plate of planetary concrete mixer adopts wear-resistant alloy lining plate, which greatly prolongs the service life of concrete mixer.

4. The excellent advantages of planetary concrete mixer make up for the problem of insufficient mixing capacity of traditional concrete mixer. Through the unique research and development of planetary concrete mixer, the mixing effect of mixer is greatly improved, and the material sticking to the mixing shaft is avoided during the mixing process. It reduces the probability of holding the shaft, and realizes high-efficiency stirring while saving electric energy.

Not only that, the planetary mixer reducer specially developed by the planetary vertical shaft mixer realizes the complete coverage of the mixture in 6 seconds. The running track is extremely complex, not only can quickly realize the mixing uniformity of the concrete mixer, but also the combination of rotation and revolution greatly enhances the material. The characteristics of the concrete mixer with high speed, labor saving, high environmental protection and high homogeneity in the process of material mixing are really amazing.

Why you want to use the planetary concrete mixer?

According to the mixing method, concrete mixers can be divided into two types: gravity mixing and forced mixing.

The self-falling gravity mixer is to put different material in a rotating mixing drum. With the rotation of the mixing drum, the blades in the drum lift the raw material to a certain height, and then freely fall down by its own gravity. Time and time again until it's well mixed. This kind of mixer generally mixes the wet concrete and some concrete which is not so high quality.

The compulsory mixer is a mixing tank that does not move, but is forcedly mixed by the blades evenly placed on the rotating shaft in the tank.

The mixer has good mixing quality and high production efficiency; however, the power consumption is large and the blades wear out quickly. Generally speaking, it is suitable for mixing dry hard concrete.

So, when you want to mix the high quality concrete, such as plastic concrete, UHPC, dry material etc, the planetary concrete mixer is highly recommended.

How to choose the suitable planetary concrete mixer?

When you want to purchase a planetary concrete mixer, there are several factors need to be considered;

- 1. Capacity, how many cubic meters per batch or per hour? HAMAC can provide our clients with the central mixer from 0.5m3 to 3m3 per batch;

- 2. What is the discharging height of the concrete mixer? Then we will see if the platform is required, and how many meters high.

- 3. If you need the weighing system for cement, water and additive? The weighing system is not a standard part of the concrete mixer.

- 4. Do you need a hoisting hopper to feed the material into the concrete mixer?

- 5. How many discharging gates you need?

FAQ for planetary concrete mixer

- 1. I need to use this concrete mixer for concrete block production line, is it suitable or not?Yes, it is the best choice for the precast concrete product. For the concrete hollow block, the concrete is not so wet as common concrete, it is a little dry, and it needs to be mixed evenly and fully;

- 2. Can I use this planetary concrete mixer for refractory material?Yes, it is. It is widely use in this filed. Not only for refractory, but also for some chemical material, dry power etc.

- 3. How to deliver the planetary concrete mixer?It depends on different models. For 0.25m3 to 1.0m3 per batch mixer, common container is required. If bigger than 1.5m3 (MPC1500), flat rack is required;

- 4. How long the warranty period?Normally speaking, it is 12 months after installation and commissioning.