What is jaw crusher?

Jaw crusher, also known as "tiger’s mouth". It is widely used in the crushing of various ores and stones in mining and smelting, building materials, highways, railways, water conservancy and chemical industries.

The higher compressive strength of the crushed material is 320Mpa. Jaw rock crusher for sale mainly used as primary and secondary crushers in mining, building materials, infrastructure and other sectors. According to the width of the feed opening, it is divided into three types: large, medium and small. The width of the feeding opening is larger than 600MM is a large machine, the width of the feeding opening is 300-600MM is a medium-sized machine, and the width of the feeding opening is less than 300MM is a small crusher machine.

Different models as options, famous brand bearings, Eccentric shaft and eccentric block are available.The jaw crushers for sale have complete specifications, and the feeding particle size is 125mm ~ 1020mm, this is the first factor to be considered for design a stone crusher plant.

How does a jaw crusher work?

The jaw rock crusher working principle as below:

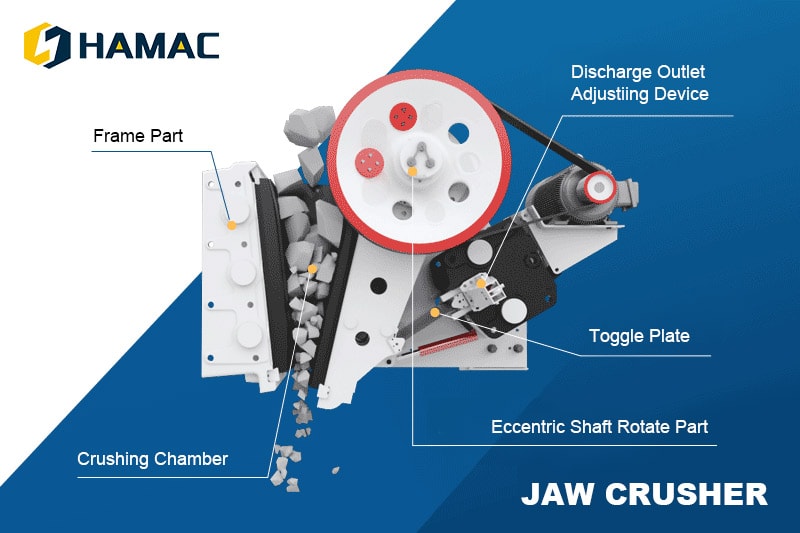

The jaw rock crusher is mainly composed of the crusher frame, the eccentric shaft rotating part, mobile jaw plate and stationary jaw platein the crushing cavity, the safety device, the discharge opening adjustment device etc. The crushing method of the jaw crusher is a curved extrusion type.

The motor drives the belt and pulley, and the movable jaw swings back and forth through the eccentric shaft. When the movable jaw pushes the movable jaw plate to move toward the stationary jaw plate, the stone is crushed.

When the movable jaw and the movable jaw plate retreat under the action of the eccentric shaft and the spring, the previously crushed materials are discharged from the lower discharge opening of the crusher jaw plate.

With the continuous rotation of the motor, the crusher jaws periodically crush and discharge materials to achieve mass production.

Highlights of jaw crusher machine for sale

- 1.Deep crushing chamber, low consumption and energy saving; optimized deep crushing chamber, no dead zone, greatly improved feeding and crushing efficiency, single machine energy saving 15%-30%, system energy saving more than double.

- 2.Strong bearing capacity and high stability. Larger forging blanks can process heavy eccentric shafts, high manganese steel jaw plates and high-grade cast steel movable jaw assemblies. The jaw crusher has stronger bearing capacity and higher stability.

- 3.Centralized lubrication system, easy to be maintained, the uniquely designed centralized lubrication system makes the lubrication of components faster and the maintenance workload is small.

- 4.The discharge adjustment range is large, one machine is multi-purpose, the gasket-type discharge adjustment device has a large discharge adjustment range, which increases the flexibility of the equipment and can meet various processing requirements of customers.

Type of jaw rock crusher for sale we have

Regarding the jaw rock crusher for sale, there are two different types of jaw crusher to be explained. PE series jaw crusher and PEX series jaw crusher.

1. PE series jaw crusher, it is the primary jaw crusher. Normally speaking, this type jaw crusher sizes feed opening are 150*250mm;

2. 250*400mm,400*600mm,500*750mm,600*900mm, 750*1060mm, 900*1200mm etc. For this series jaw crusher, the output size is medium sizes which is suitable for secondary crusher to crush them;

3. PEX series jaw crusher, it is the secondary jaw crusher. Its output size is small sizes such as 0-25mm which is final product already. The popular models of this jaw crusher machine for sale are PEX250*750, PEX250*1000,PEX250*1200,PEX300*1300. For this secondary jaw crusher for sale, it is very popular in some countries such as Indonesia, Vietnam etc. Sometimes, it is also used a crusher before the cone crusher.

How to select the jaw crusher sizes for your project?

When you want to build a stone crusher plant, there are several important factors to be considered:

- 1. The maximum stone size before crushing. From this data, the feed opening of jaw crusher can be confirmed;

- 2. How many tons or cubic meters per hour you want to process?

- 3. The feeding size of the next crushing stage.

The above three factors need to be considered together. The most important factor is the capacity of jaw crusher, even the stone size is smaller, but in order to reach the capacity, you have to choose a bigger jaw crusher. Meanwhile, you also have to consider the output size of jaw crusher, if it is suitable for the secondary crusher or not. It is a complicated stone crusher plant design, please contact our experienced expert to get more support.

FAQs of jaw crusher for sale

- 1. What is the jaw crusher HS code?Its HS code is 84742090, you can check the tariff cost from the customs with this code;

- 2. What is the jaw crusher price?The price of jaw crusher related to the model, new or used jaw crusher etc. It is a too wide range. You have to contact our sales manager for more information.

- 3. How about the jaw crusher maintenance?For the jaw crusher maintenance, it is simple, not so complicated as cone crusher. The tear and wear parts are side liner board, jaw plates. You just need to lubricate it with grease per shift. And check the jaw plate frequently to see when to replace it.