Working Principle

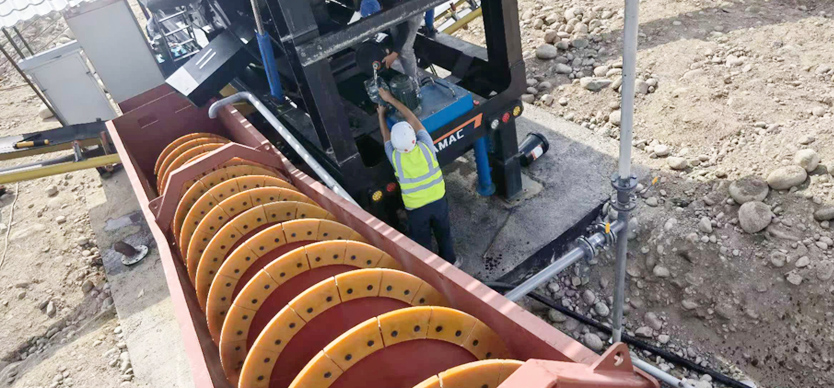

The rotor of the machine adopts a central structure, the spiral blades are installed on the central shaft, and the reducer is connected to the central shaft for operation. Mechanical classification is carried out based on the principle that the specific gravity of solid particles is different, and therefore the sedimentation speed in the liquid is different. When washing sand, the sand is continuously stirred mainly through the rotation of the spiral component, so that the mud attached to the sand is dissolved in the water, and the muddy water and other impurities such as hay flow away from the overflow port at the top with the water. The sand is continuously rotated and discharged from the outlet at the other end, thereby realizing the cleaning and screening of sand and gravel.

Advantages of sand washing machine

- 1.Good sealing structure, fully enclosed transmission device, and adjustable overflow weir plate ensure the durability of the equipment, good cleaning and dehydration, and stable fine particle products;

- 2.Large processing capacity, low power consumption, high cleaning degree, less loss of washed materials, and high selection and washing efficiency;

- 3.Long service life and less need for repairs, thus reducing costs;

- 4.The washing blade is equipped with polyurethane end, it is wearable;