HCS Hydraulic Cone Crusher Working Principle

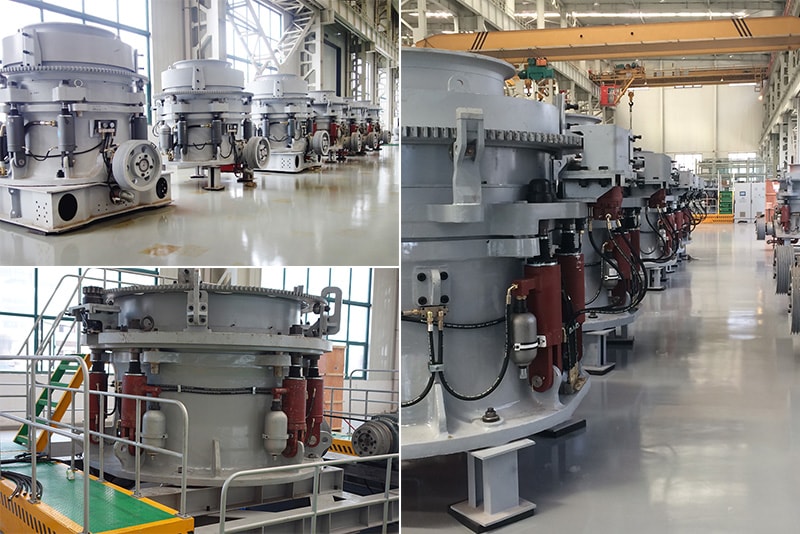

HST single cylinder hydraulic cone crusher is mainly composed of upper frame, middle frame (medium crushing type), lower frame, moving cone, eccentric sleeve, transmission, hydraulic cylinder and other parts. When working, the horizontal shaft is driven by the motor to rotate, the horizontal shaft drives the eccentric sleeve to rotate through the gear, and then the eccentric sleeve drives the moving cone to swing in a circle, thereby achieving continuous extrusion and crushing of stones.

Optimized crusher body and cavity design

The enhanced frame structure design and the key parts are inspected and accepted by non-destructive testing, which makes the crusher body stronger and the operation more reliable. The optimized crushing cavity design ensures high lamination crushing efficiency while the crushing effect of the equipment is not affected by liner wear.

Multiple modes can be switched at will

The fully automatic control system provides users with multiple control modes such as manual control, automatic loading, automatic discharge opening and automatic double discharge opening, with high visualization, which reduces the difficulty of user operation.

Positive pressure dust prevention reduces maintenance

The positive pressure dust prevention system keeps the internal pressure of the crushing cavity higher than the external pressure, effectively reducing the risk of dust or other fine particles entering the crushing cavity to contaminate the lubricating oil and damage the bearings, thus increasing the service life of the crusher and reducing maintenance workload.

Hydraulic lubrication station integration

The hydraulic station and lubrication station are designed in an integrated manner to save installation space; the hydraulic system adopts a high-pressure design to meet ordinary pressure requirements, and the equipment has a higher pressure margin when running, which improves the reliability of the hydraulic system.

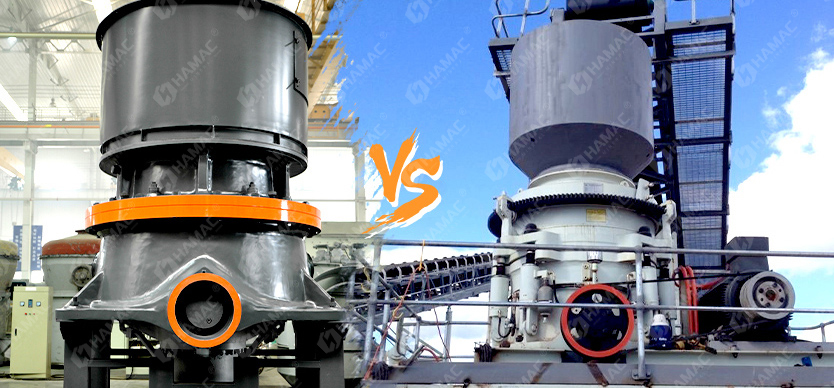

Single-cylinder vs Multi-cylinder cone crusher

HP series cone crusher and HST series cone crusher are all high-performance crushers, and they all realize the layer compression crushing process. Due to the great differences in structure, they have different advantages.

Advantages of HCS series single cylinder cone crusher:

- 1. Good force conditions for the moving cone, long life of spare parts (bearing copper parts).

- 2. Good medium crushing effect and large passing capacity.

- 3. Fully realize intelligent control, realize dynamic load adjustment of the discharge port, motor power, and crusher pressure, and can display various operating parameters in real time. Achieve unmanned operation, the discharge port is automatically detected and adjusted. Thereby exerting the maximum power of the crusher motor.

Advantages of HP series multi-cylinder cone crusher (especially large models):

- 1. The fine type cone crusher has a high content of fine particles below 8mm.

- 2. The fine crushed product has good particle shape (cubical shape and round shape) and good layer compression crushing effect.

- 3. High energy efficiency ratio of fine crushing.