HAMAC Chinese excavator succeeds in Africa

As an after-sales service engineer for HAMAC, I was fortunate enough to be assigned to the vibrant construction site in Angola, Africa, to assume key responsibilities. My main task is to monitor the performance of our company's HMC360 hydraulic crawler excavator. This excavator is specially designed to adapt to the harsh construction conditions in Africa, and its reliability and efficiency have been fully proven in actual work.

During the interaction with the construction site team, I deeply realized the importance of combining on-site practice. Every time I perform maintenance and performance optimization on the excavator, I am more convinced of the strength of our products, and it also deepens my understanding of customer needs and on-site challenges.

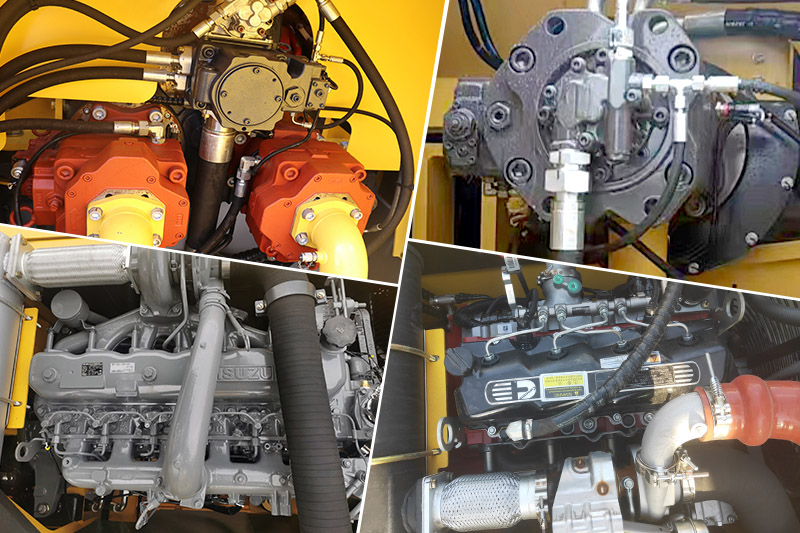

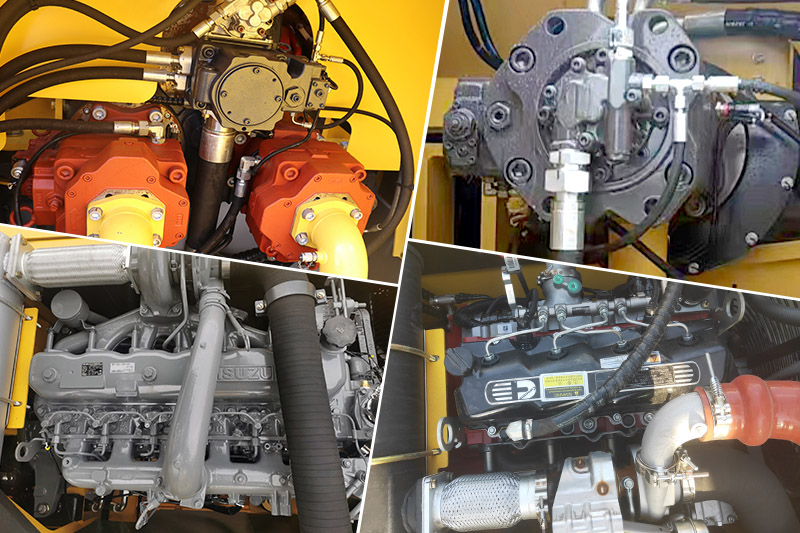

Product Overview: The HMC360 is a testament to HAMAC's dedication to innovation and excellence. Equipped with state-of-the-art engines from industry leaders such as ISUZU, CUMMINS, and WEICHAI, this excavator delivers robust performance and substantial torque, ideal for the heavy-duty operations that characterize the African construction sector.

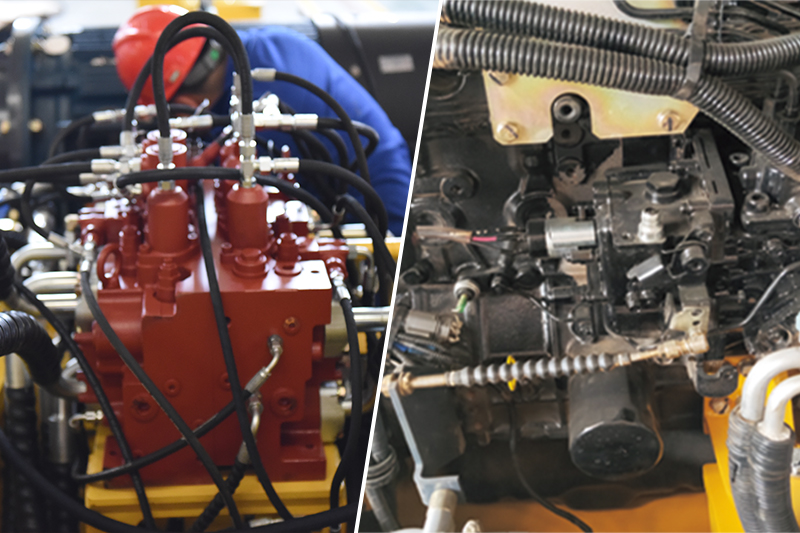

Reliability and Testing: Our commitment to quality is evident in the rigorous testing protocols that each HMC360 excavator undergoes. Each unit is subjected to a comprehensive 2000-hour industrial test regimen and must meet the stringent criteria set by the National Construction Machinery Quality Supervision and Inspection Center. This ensures that the HMC360 excavator is not only reliable but also capable of withstanding the harshest conditions prevalent on African construction sites.

Hydraulic System and Safety Features: The HMC360's hydraulic system, built with components from reputable international brands, is designed for peak reliability. The excavator's cab is fortified with anti-rollback and anti-fall structures, aligning with safety standards across regions such as China, the European Union, and North America. The machine's acquisition of TOPS and FOPS safety certifications stands as a testament to our commitment to providing a safe working environment for operators.

Maintenance Accessibility and Operational Upkeep: A key differentiator of the HMC360 excavator is its straightforward maintenance process. The strategic placement of filter elements on the main pump's side allows for swift and hassle-free maintenance. This design innovation minimizes downtime and maximizes the excavator's availability, ensuring that maintenance can be conducted efficiently without compromising the operation.

Practical applications and operator experience: In the field, the HMC360 excavator has proven its worth on a variety of construction projects from residential developments to infrastructure construction. Its powerful engine and resilient structure allow it to easily traverse the abrasive sand and soil common in the area. The excavator's large bucket capacity and powerful digging force speed up the excavation of deep trenches.

Conclusion and Forward-looking Perspective: Working in Angola deepened my understanding of the importance of the HMC360 excavator in improving local construction capabilities. Its blend of power, durability, safety, and maintenance-friendly design positions it as the preferred choice for construction firms navigating challenging environments. As HMAC continues to pursue technological innovation, the HMC360 excavator will continue to lead the industry standard and provide reliable support for global construction projects. We will continue to optimize product performance to ensure that it adapts to future construction challenges and creates continued value for customers.

If you want to visit this project on site, or contact our client to check the machine’s work performance, please contact us: Email:sales@hamacchina.com WhatsApp:+8615136236223