Artificial sand making production line

With the reduction of natural sand resources and the advancement of artificial sand crushing equipment, artificial sand is increasingly favored by people. Hereby, we will explain you a standard artificial sand making production line.

Sand making plant in Dominican

The working flow chart:

The stone is evenly fed by the vibrating feeder to the jaw crusher for coarse crushing. The crushed material enters the cone crusher for secondary crushing. The stones with the suitable size are entered into the vertical shaft impact crusher (sand making machine) for sand making. The materials that do not meet the requirements are returned to the cone crusher for re-crushing to form a closed loop.

The crushed stone coming out of the vertical shaft impact sand making machine are conveyed to the vibrating screen for screening, and the qualified ones are conveyed to the sand washing machine for cleaning. If it does not meet the size requirements, it will be sent to the sand making machine to be crushed again to form a second closed-circuit cycle.

The production line will eventually form a two-stage closed-circuit cycle, and various configurations can also be made according to the specific conditions and needs of customers.

300 tons per artificial sand making and washing plant

300 tons per artificial sand making and washing plant

Please contact our expert for more solutions. We can provide you with special design based on your requirement.

Working site of Artificial sand making production line

The Artificial sand making production line is widely used for different projects all over the world. HAMAC exported the Artificial sand making production line to different countries and got good comments from our clients. They are used in different working sites for different projects.

250tph stationary crushing and screening plant in China

Application Country: China

250tph stationary crushing and screening plant in China

Application Country: China

This 250tph stationary crushing and screening plant was installed in 2012 in China. Our clients came to our city visited many manufacturers of the crushing and screening plant. We had a meeting with our client together with our chief engineer.…

150tph stationary crushing and screening plant in Iraq

Application Country: Iraq

150tph stationary crushing and screening plant in Iraq

Application Country: Iraq

This 150tph stationary crushing and screening plant was installed in 2011 in Iraq. It was installed in a mountain valley. Up to now, it still works smoothly. This client purchased blow bar, jaw plate, line board, screen mesh, rollers for belt conveyor every year. It is a good business in that area. Almost all the aggregates are supplied by this …

Jaw Crusher

Jaw Crusher

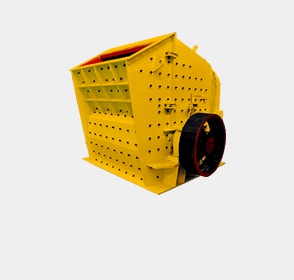

Impact Crusher

Impact Crusher

S series Spring Cone Crusher

S series Spring Cone Crusher

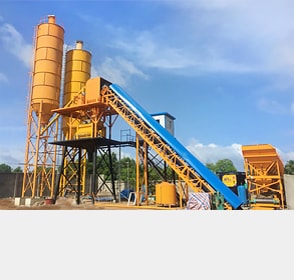

Stationary Concrete Batching Plant

Stationary Concrete Batching Plant